Picture 1

Ultrasonic Testing uses the same principle as is used in

naval SONAR and fish finders. Ultra-high frequency sound is introduced into the

part being inspected and if the sound hits a material with a different acoustic

impedance (density and acoustic velocity), some of the sound will reflect back

to the sending unit and can be presented on a visual display. By knowing the

speed of the sound through the part (the acoustic velocity) and the time

required for the sound to return to the sending unit, the distance to the

reflector (the indication with the different acoustic impedance) can be

determined. The most common sound frequencies used in UT are between 1.0 and

10.0 MHz, which are too high to be heard and do not travel through air. The

lower frequencies have greater penetrating power but less sensitivity (the

ability to "see" small indications), while the higher frequencies

don't penetrate as deeply but can detect smaller indications.

The two most commonly used types of sound waves used in

industrial inspections are the compression (longitudinal) wave and the shear

(transverse) wave, as shown in picture 1. Compression waves cause the atoms in

a part to vibrate back and forth parallel to the sound direction and shear

waves cause the atoms to vibrate perpendicularly (from side to side) to the

direction of the sound. Shear waves travel at approximately half the speed of

longitudinal waves.

Sound is introduced into the part using an ultrasonic

transducer ("probe") that converts electrical impulses from the UT

machine into sound waves, then converts returning sound back into electric

impulses that can be displayed as a visual representation on a digital or LCD

screen (on older machines, a CRT screen). If the machine is properly

calibrated, the operator can determine the distance from the transducer to the

reflector, and in many cases, an experienced operator can determine the type of

discontinuity (like slag, porosity or cracks in a weld) that caused the

reflector. Because ultrasound will not travel through air (the atoms in air

molecules are too far apart to transmit ultrasound), a liquid or gel called

"couplant" is used between the face of the transducer and the surface

of the part to allow the sound to be transmitted into the part.

UT Techniques

Straight Beam

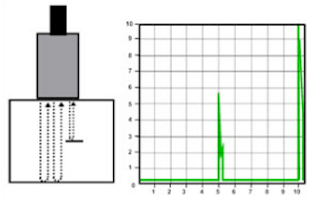

Picture 2

Straight beam inspection uses longitudinal waves to

interrogate the test piece as shown at the right. If the sound hits an internal

reflector, the sound from that reflector will reflect to the transducer faster

than the sound coming back from the back-wall of the part due to the shorter

distance from the transducer. This results in a screen display like that shown

at the right in Picture 2. Digital thickness testers use the same process, but

the output is shown as a digital numeric readout rather than a screen

presentation.

Angle Beam

Picture 3

Angle beam inspection uses the same type of transducer but

it is mounted on an angled wedge (also called a "probe") that is

designed to transmit the sound beam into the part at a known angle. The most

commonly used inspection angles are 45o, 60o and 70o, with the angle being

calculated up from a line drawn through the thickness of the part (not the part

surface). A 60o probe is shown in Picture 3. If the frequency and wedge angle

is not specified by the governing code or specification, it is up to the

operator to select a combination that will adequately inspect the part being

tested.

In angle beam inspections, the transducer and wedge

combination (also referred to as a "probe") is moved back and forth

towards the weld so that the sound beam passes through the full volume of the

weld. As with straight beam inspections, reflectors aligned more or less

perpendicular to the sound beam will send sound back to the transducer and are

displayed on the screen.

Immersion Testing

Picture 4

Immersion Testing is a technique where the part is immersed

in a tank of water with the water being used as the coupling medium to allow

the sound beam to travel between the transducer and the part. The UT machine is

mounted on a movable platform (a "bridge") on the side of the tank so

it can travel down the length of the tank. The transducer is swivel-mounted on

at the bottom of a waterproof tube that can be raised, lowered and moved across

the tank. The bridge and tube movement permits the transducer to be moved on

the X-, Y- and Z-axes. All directions of travel are gear driven so the

transducer can be moved in accurate increments in all directions, and the

swivel allows the transducer to be oriented so the sound beam enters the part

at the required angle. Round test parts are often mounted on powered rollers so

that the part can be rotated as the transducer travels down its length,

allowing the full circumference to be tested. Multiple transducers can be used

at the same time so that multiple scans can be performed.

Through Transmission

Through transmission inspections are performed using two

transducers, one on each side of the part as shown in Picture 4. The

transmitting transducer sends sound through the part and the receiving

transducer receives the sound. Reflectors in the part will cause a reduction in

the amount of sound reaching the receiver so that the screen presentation will

show a signal with a lower amplitude (screen height).

Phased Array

Phased array inspections are done using a probe with multiple

elements that can be individually activated. By varying the time when each

element is activated, the resulting sound beam can be "steered", and

the resulting data can be combined to form a visual image representing a slice

through the part being inspected.

Time of Flight Diffraction

Time of Flight Diffraction (TOFD) uses two transducers

located on opposite sides of a weld with the transducers set at a specified

distance from each other. One transducer transmits sound waves and the other

transducer acting as a receiver. Unlike other angle beam inspections, the

transducers are not manipulated back and forth towards the weld, but travel

along the length of the weld with the transducers remaining at the same

distance from the weld. Two sound waves are generated, one travelling along the

part surface between the transducers, and the other travelling down through the

weld at an angle then back up to the receiver. When a crack is encountered,

some of the sound is diffracted from the tips of the crack, generating a low

strength sound wave that can be picked up by the receiving unit. By amplifying

and running these signals through a computer, defect size and location can be

determined with much greater accuracy than by conventional UT methods.

0 komentar:

Post a Comment