RADIOGRAPHY TEST

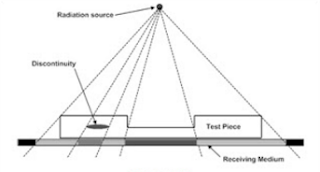

Industrial radiography involves exposing a test object to

penetrating radiation so that the radiation passes through the object being

inspected and a recording medium placed against the opposite side of that

object. For thinner or less dense materials such as aluminum, electrically

generated x-radiation (X-rays) are commonly used, and for thicker or denser

materials, gamma radiation is generally used.

Gamma radiation is given off by decaying radioactive

materials, with the two most commonly used sources of gamma radiation being

Iridium-192 (Ir-192) and Cobalt-60 (Co-60). IR-192 is generally used for steel

up to 2-1/2 - 3 inches, depending on the Curie strength of the source, and

Co-60 is usually used for thicker materials due to its greater penetrating

ability.

The recording media can be industrial x-ray film or one of

several types of digital radiation detectors. With both, the radiation passing

through the test object exposes the media, causing an end effect of having

darker areas where more radiation has passed through the part and lighter areas

where less radiation has penetrated. If there is a void or defect in the part,

more radiation passes through, causing a darker image on the film or detector,

as shown in Figure 8.

RT Techniques

Film Radiography

Film radiography uses a film made up of a thin transparent

plastic coated with a fine layer of silver bromide on one or both sides of the

plastic. When exposed to radiation these crystals undergo a reaction that

allows them, when developed, to convert to black metallic silver. That silver

is then "fixed" to the plastic during the developing process, and

when dried, becomes a finished radiographic film.

To be a usable film, the area of interest (weld area, etc.)

on the film must be within a certain density (darkness) range and must show

enough contrast and sensitivity so that discontinuities of interest can be

seen. These items are a function of the strength of the radiation, the distance

of the source from the film and the thickness of the part being inspected. If

any of these parameters are not met, another exposure ("shot") must

be made for that area of the part.

Computed Radiography

Computed radiography (CR) is a transitional technology

between film and direct digital radiography. This technique uses a reusable,

flexible, photo-stimulated phosphor (PSP) plate which is loaded into a cassette

and is exposed in a manner similar to traditional film radiography. The

cassette is then placed in a laser reader where it is scanned and translated

into a digital image, which take from one to five minutes. The image can then

be uploaded to a computer or other electronic media for interpretation and

storage.

Computed Tomography

Computed tomography (CT) uses a computer to reconstruct an

image of a cross sectional plane of an object as opposed to a conventional

radiograph, as shown in Figure 9. The CT image is developed from multiple views

taken at different viewing angles that are reconstructed using a computer. With

traditional radiography, the position of internal discontinuities cannot be

accurately determined without making exposures from several angles to locate

the item by triangulation. With computed tomography, the computer triangulates

using every point in the plane as viewed from many different directions.

Digital Radiography

Digital radiography (DR) digitizes the radiation that passes

through an object directly into an image that can be displayed on a computer

monitor. The three principle technologies used in direct digital imaging are

amorphous silicon, charge coupled devices (CCDs), and complementary metal oxide

semiconductors (CMOSs). These images are available for viewing and analysis in

seconds compared to the time needed to scan in computed radiography images. The

increased processing speed is a result of the unique construction of the

pixels; an arrangement that also allows a superior resolution than is found in

computed radiography and most film applications.