Leak Testing,

Leak Testingas the name implies, is used to detect through leaks using one of the four major LT techniques: Bubble, Pressure Change, Halogen Diode and Mass Spectrometer Testing. These techniques are described below.

Leak Testingas the name implies, is used to detect through leaks using one of the four major LT techniques: Bubble, Pressure Change, Halogen Diode and Mass Spectrometer Testing. These techniques are described below.

LT Techniques

Bubble Leak Testing

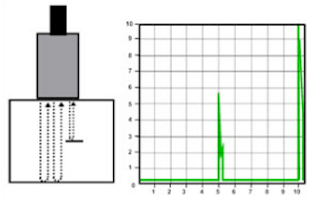

Bubble Leak Testing, as the name implies, relies on the visual detection of a gas (usually air) leaking from a pressurized system. Small parts can be pressurized and immersed in a tank of liquid and larger vessels can be pressurized and inspected by spraying a soap solution that creates fine bubbles to the area being tested. For flat surfaces, the soap solution can be applied to the surface and a vacuum box Pic 1 can be used to create a negative pressure from the inspection side. If there are through leaks, bubbles will form, showing the location of the leak.

Pressure Change Testing

Pressure Change Testing can be performed on closed systems only. Detection of a leak is done by either pressurizing the system or pulling a vacuum then monitoring the pressure. Loss of pressure or vacuum over a set period of time indicates that there is a leak in the system. Changes in temperature within the system can cause changes in pressure, so readings may have to be adjusted accordingly.

Halogen Diode Testing

Halogen Diode Testing is done by pressurizing a system with a mixture of air and a halogen-based tracer gas. After a set period of time, a halogen diode detection unit, or "sniffer", is used to locate leaks.

Bubble Leak Testing

Pic 1 : Leak Test

Pressure Change Testing

Halogen Diode Testing

Halogen Diode Testing is done by pressurizing a system with a mixture of air and a halogen-based tracer gas. After a set period of time, a halogen diode detection unit, or "sniffer", is used to locate leaks.

Mass Spectrometer Testing

Mass Spectrometer Testing can be done by pressurizing the test part with helium or a helium/air mixture within a test chamber then surveying the surfaces using a sniffer, which sends an air sample back to the spectrometer. Another technique creates a vacuum within the test chamber so that the gas within the pressurized system is drawn into the chamber through any leaks. The mass spectrometer is then used to sample the vacuum chamber and any helium present will be ionized, making very small amounts of helium readily detectable.